Paloma

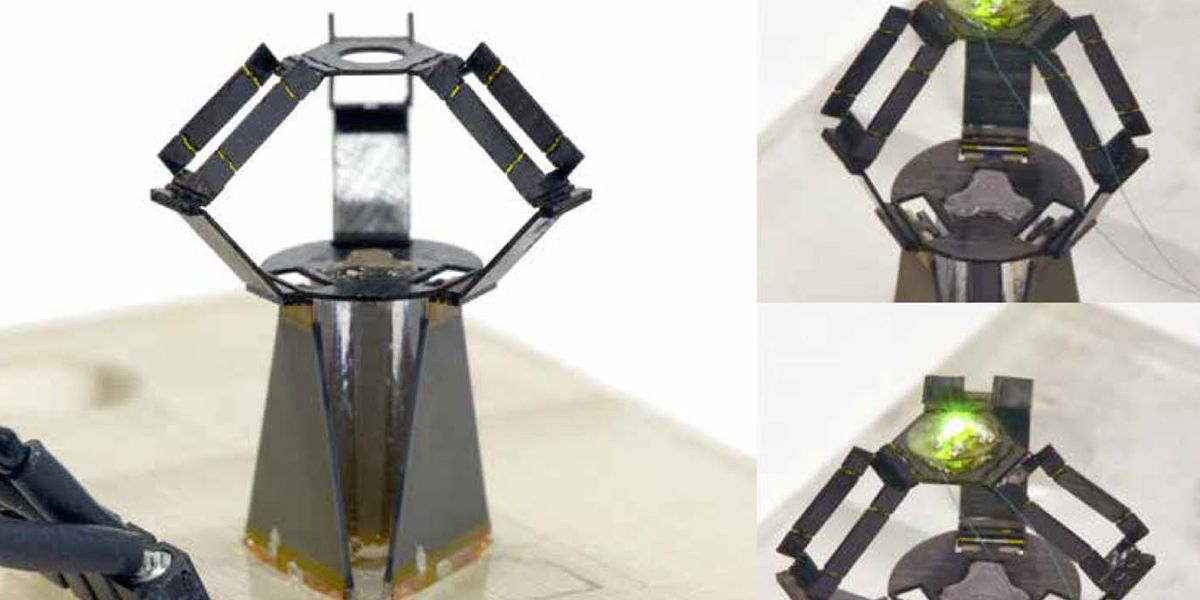

Paloma is a fully automated food-packaging machine. It uses high-speed arms called delta robots, which are positioned above a conveyor belt. Guided by a vision system, the robots move incredibly fast to pick and package fresh and frozen food items, including cookies, cakes, candy, cheese, pizza, fish, and meat.

- Creator

(Demaurex is part of the Rotzinger Group.)

- Year

- 2014

- Country

- Switzerland 🇨🇭

- Categories

- Features

Did you know?

Paloma robots can handle almost any kind of food: fresh, chilled, frozen. Of course, it can also handle non-food items.

History

Paloma was developed by Demaurex, a pioneer in industrial robotics based in Ecublens, near Lausanne, Switzerland. Founded in 1983, Demaurex focused initially on producing mechanical parts for automation and computer systems. One of those was an early version of the Logitech computer mouse. In 1988, Demaurex acquired a license to commercialize the delta robot. Invented at the nearby École Polytechnique Fédérale de Lausanne (EPFL), the delta robot consists of three arms suspended from above and attached to an end-effector, a configuration that allows it to move extremely fast and precisely. In subsequent years, Demaurex developed a successful line of robotic systems, and in 1996 it bought the delta robot patent. In 2018, Demaurex became part of the Rotzinger Group. It currently offers a variety of pick-and-place robots for the food, pharmaceutical, and other industries.

Specs

- Overview

Up to 100 picks per minute, payload up to 3 kg, per robot. Can load items from the top or side. Can handle primary and secondary packaging. Up to six robots can be grouped together. Integrated vision system. Can handle fresh, chilled, and frozen foods. Paloma WD model: Easy-to-clean and hygienic design, can be fully washed down.

- Status

Ongoing

- Year

2014

- Website

- Width

- 195 cm

- Height

- 272 cm

- Length

- 480 cm (3 robots)

- Sensors

One industrial-grade camera to detect items. Encoders on conveyor belt.

- Actuators

GD series Delta robots

- Degrees of Freedom (DoF)

- 3 DoF per delta robot (additional end-effector options: 1 DoF rotation, 1 DoF tilt)

- Materials

Stainless steel, sheet metal.

- Compute

Supervisory computer: Rexroth industrial PC. Delta robot computers: Beckhoff industrial PC. Windows OS. Touchscreen interface. Custom control cabinets, positioned on top of the machine.

- Software

Gemini control software platform

- Power

Transformer: 3 x 400 V AC. Consumption: 6 kVA (2 or 3 robot cell, 1 vacuum pump)